To create medical devices that perform optimally, medical device laser welding manufacturers must pay close attention to the materials and processes used in construction.

With traditional welding methods, it can be difficult to create a weld that is strong enough to stand up to the demands of the medical industry. Laser welds are extremely strong and can be made with a high degree of precision, making laser welding medical devices ideal.

How Does Laser Welding Work?

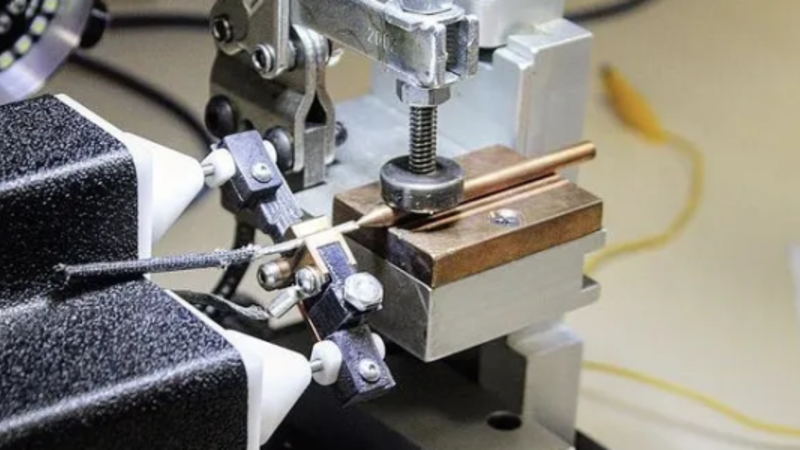

Laser welding is a process that uses a concentrated beam of light to create a weld. The laser beam heats the material until it reaches its melting point, at which point the two pieces of material will fuse together. This process can be used on various materials, including metals, plastics, and ceramics.

Efficiency

One of the benefits of laser welding is that it can be performed very quickly. The speed at which the laser beam moves across the surface of the material can be controlled, which means that manufacturers can weld small components in a matter of seconds.

Additionally, laser welding medical devices can be done without having to apply any additional pressure to the materials being joined. This makes it ideal for use in delicate medical devices.

Advantageous

There are several advantages to using laser welds in medical devices. First, as mentioned above, laser welds are very strong and can withstand a great deal of force. This is important for devices that will be subjected to repeated use or extreme conditions.

Additionally, laser welds are very precise, which is essential for ensuring that devices function properly and do not pose any risks to patients.

Another advantage of laser welding is that it causes less damage to the surrounding material than other welding methods. This is important for preventing damage to sensitive components in medical devices.

Additionally, because there is no need to apply pressure during laser welding, there is also less risk of distortion or warping of the materials being joined.